Modern tunnelling is subject to numerous demands: tunnelling companies must keep costs low, finish projects in less time and still keep up with the high quality and safety standards.

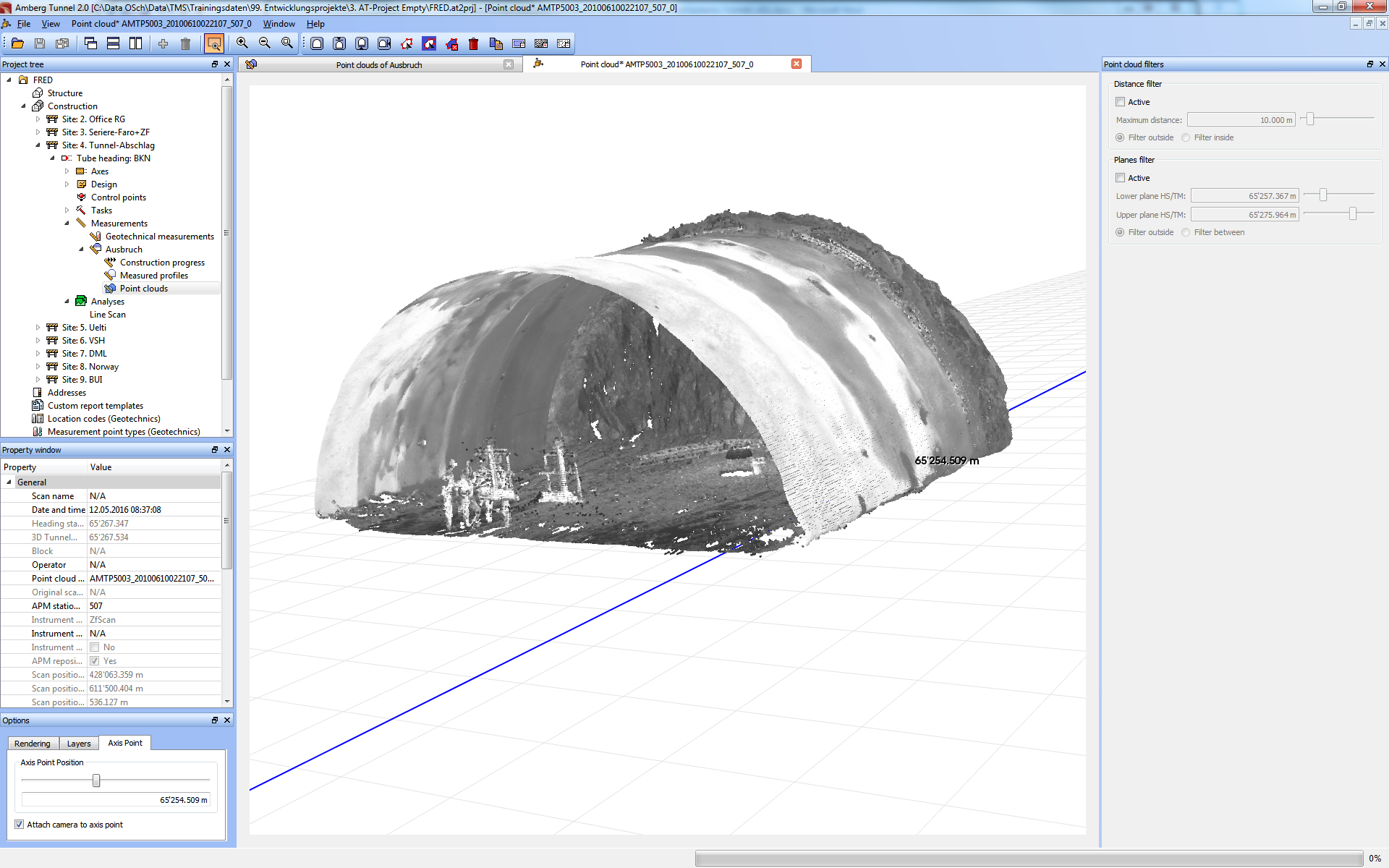

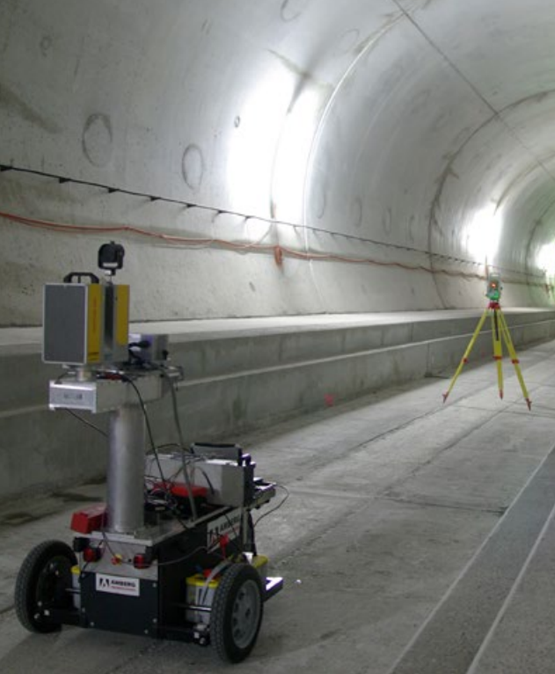

Tunnel surveying is one of the core competencies of Amberg Technologies AG. The comprehensive surveying services and the use of innovative measurement solutions contribute significantly to the promotion of efficient construction processes and high project safety.

Many years of experience paired with innovative Amberg surveying solutions - Our tunnel surveying experts offer all surveying and monitoring tasks for every construction phase from a single source.

The following services are provided by our new organisation Amberg Infra 7D. Learn more and get in touch at www.amberginfra7d.com