Amberg Tunnel offers a complete set of tools to efficiently process data collected in TBM tunnels and create reports. Point clouds and total station measurements seamlessly convert into meaningful results.

The primary tools are:

- Circularity/Ovalisation analysis (profiles)

- Radial displacement analysis (geotechnics)

- Undulation analysis (point clouds)

All the tools are useful also in other circular shaped excavations (for example shafts).

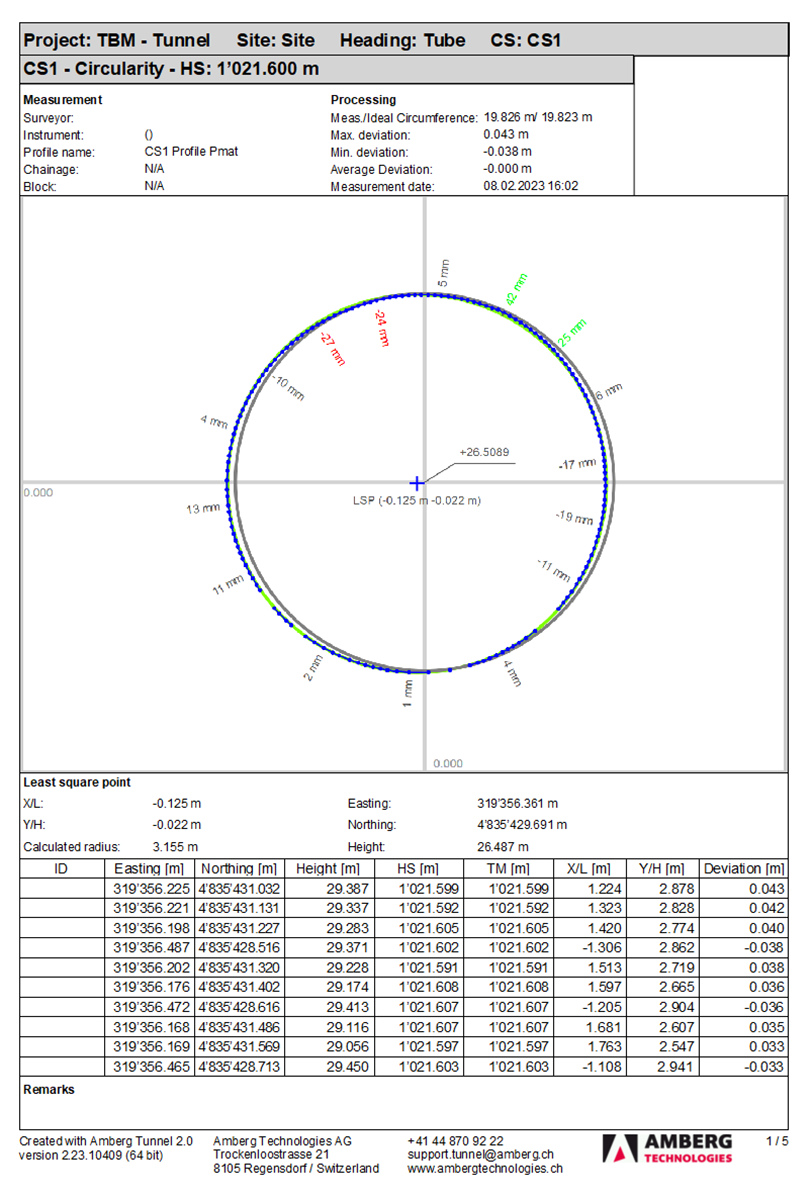

Circularity analysis

Circularity analysis gives an indication of how well the TBM segmented tunnel has been placed during construction.

Whether the profile was measured by a total station, or it is a slice from a point cloud, this analysis will calculate the perfect centre (least square point) and deviations from the circle.

The least square point represents the centre of the “as-built” tunnel, and it is typically slightly shifted from the design axis. This is caused by deviations during the TBM drive. It is very important to use the “as-built” center of the tunnel for a circularity analysis. This way the shift and the deformation are reported separately, giving proper information about the tunnel as-built.

User can set the radius of the reference circle or simply use a best-fit circle. Graphic output of the analysis will show you the deviations and highlight values over the tolerance. You can also export all the values as a table.

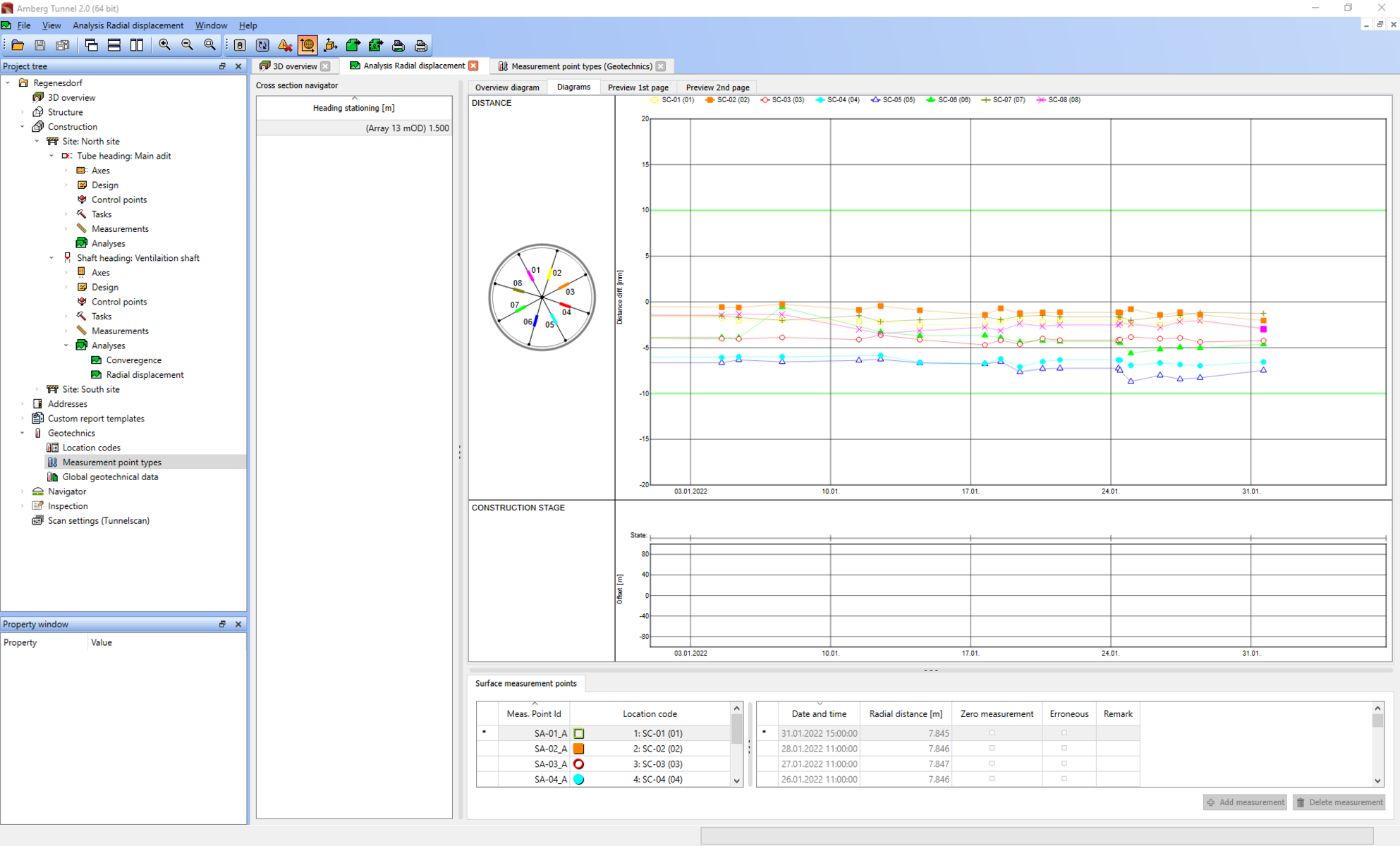

Radial displacement analysis

After the initial assessment of the tunnel circularity, it is important to keep track of the changes. Radial displacement analysis shows how the shape of the tunnel is developing over time. You can set a warning and a critical limit that will help you quickly evaluate the changes.

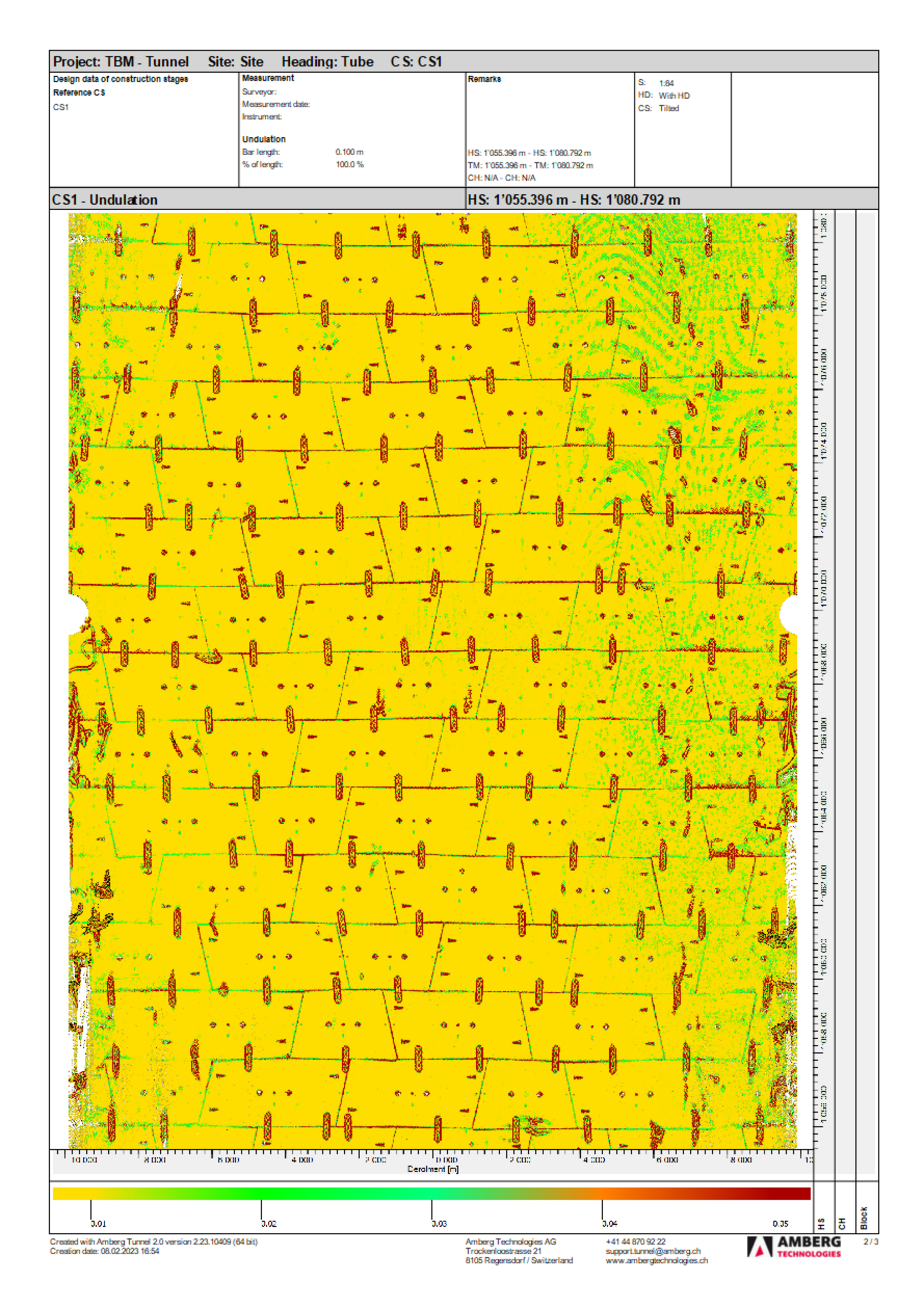

Undulation analysis

Undulation analysis highlights all uneven surfaces on the tunnel walls. It usually shows us where the tunnel needs some rework before the application of a waterproofing membrane. In TBM tunnels, we can use the same analysis to see jumps between the segments.

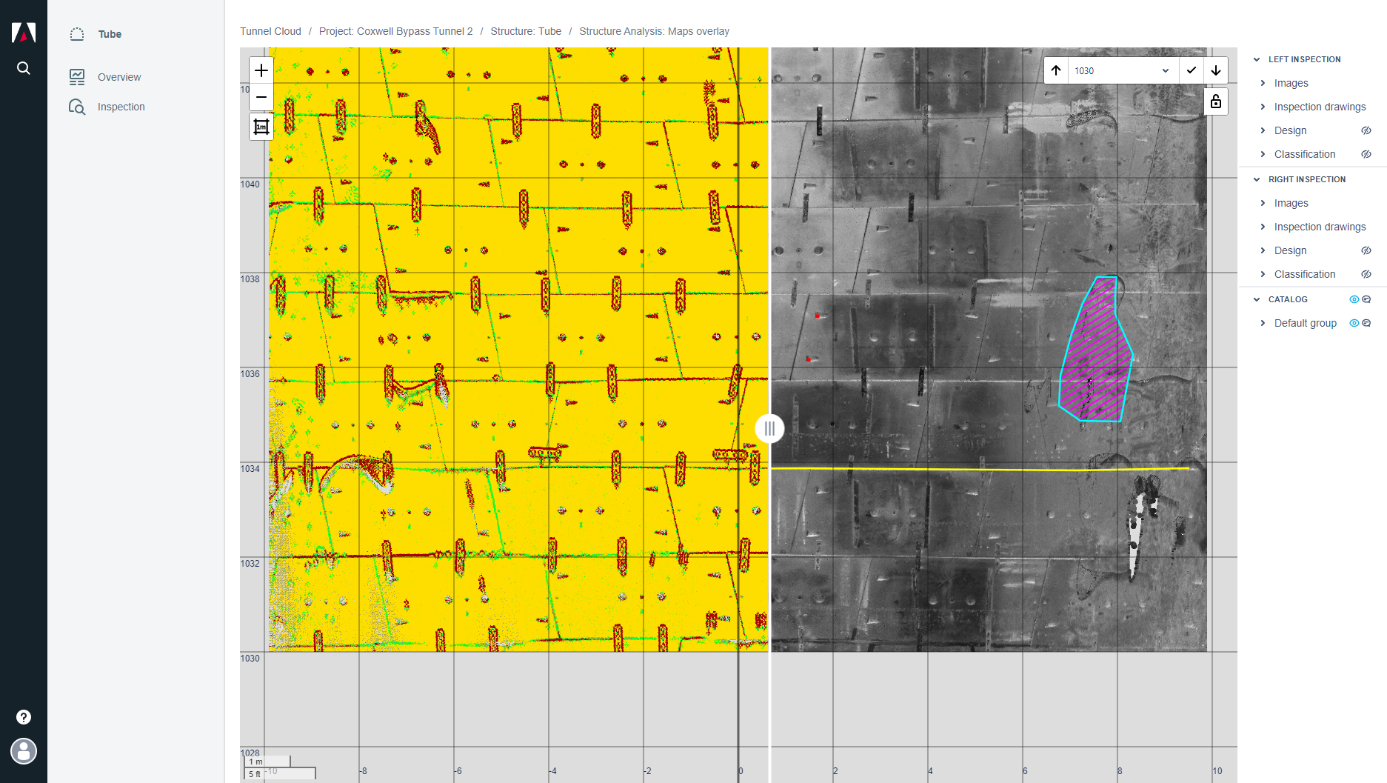

Tunnel lifecycle – Amberg Inspection

The data collected during tunnel construction are valuable also after the tunnel opening. When the tunnel must be inspected and maybe needs some repairs, it is a big help to look back and compare the current state with the as-built.

Is the gap between segments from the beginning? Or has it grown over time? Amberg Inspection will ease understanding of the technical state of the tunnel and give you tools for reliable tunnel inspection.